7.3 KiB

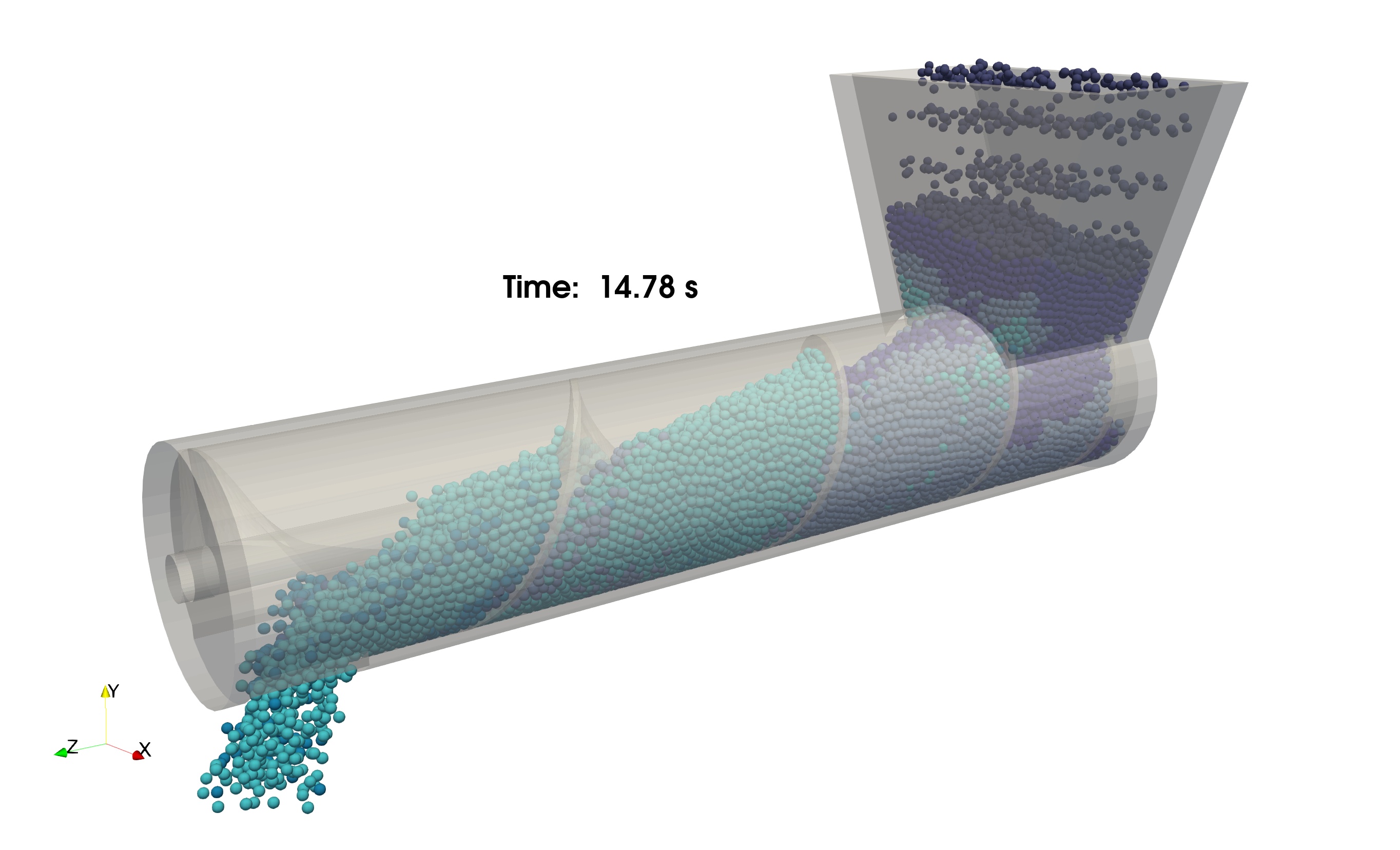

Simulating a Screw Conveyor

Problem Definition

The problem is to simulate a screw conveyor with a diameter of 0.2 m and a length of 1 m with a variable pitch. It is filled with 10 mm and 9 mm spherical particles. The timestep for integration is 0.00002 s. Particles are inserted from the top of the feeder at a rate of 2800 particles/s. The number composition of large and small particles is 2:1.

Setting Up the Case

PhasicFlow simulation case setup is based on the text-based scripts provided in two folders located in the simulation case folder: settings and caseSetup. All commands should be entered in the terminal while the current working directory is the simulation case folder (at the top level of caseSetup and settings).

Creating Particles

Open the file settings/particlesDict. Two dictionaries, positionParticles and setFields, position particles and set the field values for the particles. In the dictionary positionParticles, the positioning method is empty, which means that there are no particles in the simulation at the start.

positionParticles

{

// A list of options are: ordered, random

method empty; // creates the required fields with zero particles (empty).

mortonSorting Yes; // perform initial sorting based on morton

}

Enter the following command in the terminal to create the particles and store them in the 0 folder:

> particlesPhasicFlow

Creating Geometry

In the file settings/geometryDict, you can provide information for creating geometry. Each simulation should have a motionModel that defines a model for moving the surfaces in the simulation. The rotatingAxis model defines a fixed axis which rotates around itself. The dictionary rotAxis defines a motion component with p1 and p2 as the endpoints of the axis and omega as the rotation speed in rad/s. You can define more than one motion component in a simulation.

motionModel rotatingAxisMotion;

rotatingAxisMotionInfo

{

rotAxis

{

p1 (0 0 0.0); // first point for the axis of rotation

p2 (0 0 1.0); // second point for the axis of rotation

omega 3.14; // rotation speed (rad/s)

startTime 1; // when t>1 s, rotation starts

endTime 30; // when t>30 s, rotation stops

}

}

In the dictionary surfaces, you can define all the surfaces in the simulation. Two main options are available: built-in geometries in PhasicFlow, and providing surfaces with an STL file (ASCII format). Here we use stlWall as a method to provide the surface information through STL files. In the shell dictionary, material is set to prop1 and motion is set to none (meaning this surface is fixed). helix defines the screw at the center of the cylindrical part of the shell. For this surface, material is set to prop1 and motion is set to rotAxis.

surfaces

{

helix

{

type stlWall; // type of the wall

file screw.stl; // file name in stl folder

material prop1; // material name of this wall

motion rotAxis; // motion component name

}

shell

{

type stlWall; // type of the wall

file shell.stl; // file name in stl folder

material prop1; // material name of this wall

motion none; // this surface is not moving ==> none

}

}

Enter the following command in the terminal to create the geometry and store it in the 0/geometry folder:

> geometryPhasicFlow

Defining Properties and Interactions

In the file caseSetup/interaction, you will find properties of materials. materials defines a list of material names in the simulation and densities sets the corresponding density of each material name. The model dictionary defines the interaction model for particle-particle and particle-wall interactions. contactForceModel selects the model for mechanical contacts (here nonlinear model with limited tangential displacement) and rollingFrictionModel selects the model for calculating rolling friction. Other required properties should be defined in this dictionary.

materials (prop1); // a list of materials names

densities (2300.0); // density of materials [kg/m3]

contactListType sortedContactList;

model

{

contactForceModel nonLinearNonLimited;

rollingFrictionModel normal;

Yeff (1.0e6); // Young modulus [Pa]

Geff (0.8e6); // Shear modulus [Pa]

nu (0.25); // Poisson's ratio [-]

en (0.8); // coefficient of normal restitution

mu (0.3); // dynamic friction

mur (0.2); // rolling friction

}

The dictionary contactSearch sets the methods for broad search. method specifies the algorithm for finding the neighbor list for particle-particle contacts. updateInterval sets the intervals (in terms of the number of iterations) between each occurrence of updating the neighbor list, and sizeRatio sets the size of enlarged cells (with respect to particle diameter) for finding the neighbor list. A larger sizeRatio includes more particles in the neighbor list, requiring less frequent updates.

contactSearch

{

method NBS; // method for broad search

updateInterval 10;

sizeRatio 1.1;

cellExtent 0.55;

adjustableBox Yes;

}

In the file caseSetup/shapes, you can define a list of names for shapes, a list of diameters for shapes, and their materials names.

names (sphere1 sphere2); // names of shapes

diameters (0.01 0.009); // diameter of shapes

materials (prop1 prop1); // material names for shapes

Other settings for the simulation can be set in the file settings/settingsDict. The dictionary domain defines a rectangular bounding box with two corner points for the simulation. Each particle that gets out of this box will be deleted automatically.

dt 0.00002; // time step for integration (s)

startTime 0; // start time for simulation

endTime 20; // end time for simulation

saveInterval 0.025; // time interval for saving the simulation

timePrecision 4; // maximum number of digits for time folder

g (0 -9.8 0); // gravity vector (m/s2)

writeFormat binary; // field files will be saved in binary format

...

Running the Case

The solver for this simulation is sphereGranFlow. Enter the following command in the terminal. Depending on the computational power, it may take a few minutes to a few hours to complete:

> sphereGranFlow

Post Processing

After finishing the simulation, you can render the results in ParaView. To convert the results to VTK format, enter the following command in the terminal. This will convert all the results (particles and geometry) to VTK format and store them in the VTK/ folder:

> pFlowToVTK --binary -f diameter id velocity